Innovative Solutions for Oilfield Operations

Flotech Engineering & Consultants Global (FEC Global) specializes in delivering precision-engineered components and services across various industries, including oil and gas.

- Downhole Tools: Leveraging our extensive expertise, we manufacture stabilizers, sleeves, radial bearings, PDC thrust bearings, drill collars, and rotary subs using advanced CNC technology, specialized hard-facing techniques, surface protective coatings, and rigorous quality control aligned with API and oilfield standards, which we supply to leading directional drilling companies worldwide.

- Raw Materials: We stock and supply steel and non-magnetic material bars in various sizes, from approved mills around the globe.

- Welding & Thermal Spray: We stock and supply metal specialized powders for thermal spray, welding wires, electrodes, cladding materials in alliance with top-tier OEMs. We also supply equipment and spares for welding, cladding, and thermal spray systems.

- Valves & Control Systems: We supply a wide range and sizes of valves (gate, ball, check, butterfly) and control systems for regular and cryogenic applications for oil and gas, petrochemicals, and water treatment industry.

- Refinery Chemicals: We offer catalysts, corrosion inhibitors, demulsifiers, descaling agents, and more to enhance refining processes and operational efficiency.

- Other Chemicals: We provide drilling fluids, scale removers, and water treatment chemicals to ensure compliance and performance.

Our operations are supported by strong quality control, vast experience, and an advanced ERP system, ensuring we exceed client expectations with reliable, high-performance solutions.

Explore our comprehensive range of solutions designed to enhance performance and maximize productivity across demanding environments.

Downhole Tools

Manufacturing

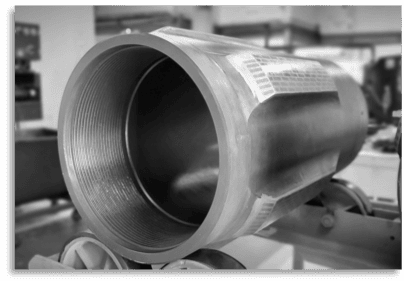

- FEC Global employs state of the art CNC machines to manufacture various parts to ensure precision and accuracy to drawing size. Parts are strictly manufactured to the customer drawing and specification. Parts are manufactured in various size and specifications.

- Delivery times are shortened by ensuring the raw material, both magnetic and non-magnetic material, are always in stock as per customer’s consumption requirement.

- Wide range of threads are machined as per the customer’s requirement. Threads are checked for their profile and integrity for added quality assurance.

- Phosphating or painting is performed in line with customer’s requirement.

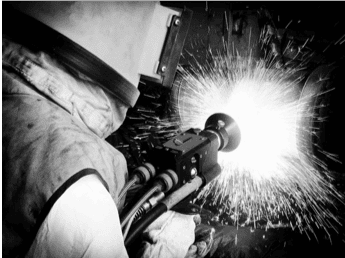

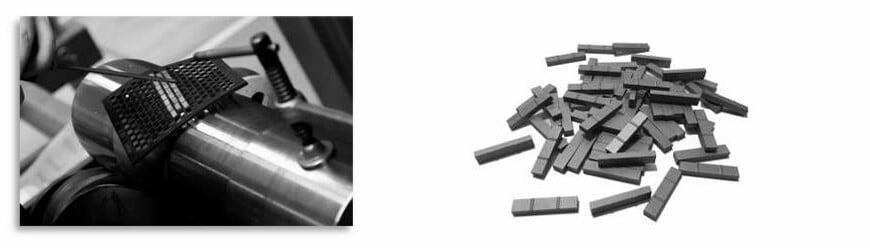

- FEC RAPTOR hard facing is our indigenous process that uses tungsten carbide based tiled inserts which is used for hard facing parts like stabilizer blades, stabilizer sleeves and radial bearing sleeves.

Following products are manufactured in various sizes and material that strictly in comply to customer drawings and specifications.

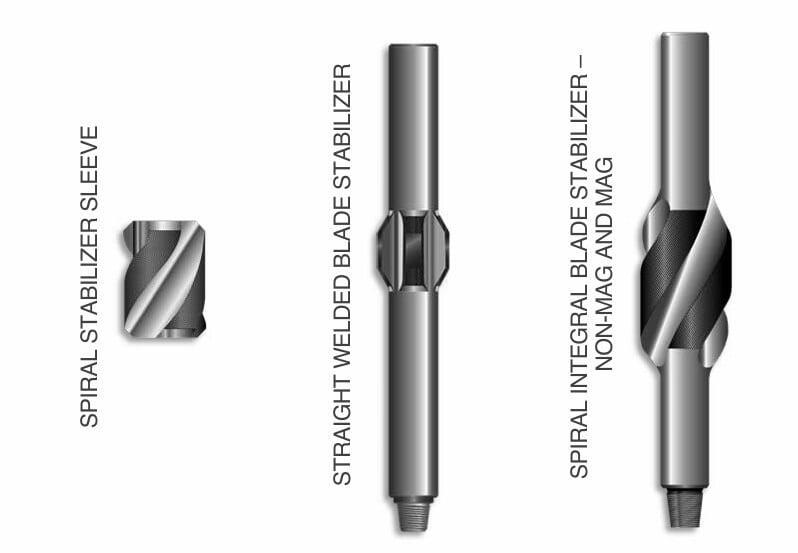

• Stabilizers - Integral blade, both Spiral and Straight blade, - Welded blade Stabilizers

• Stabilizer Sleeves

• Radial Bearings - Internal & External Sleeves

• Crossovers & Subs

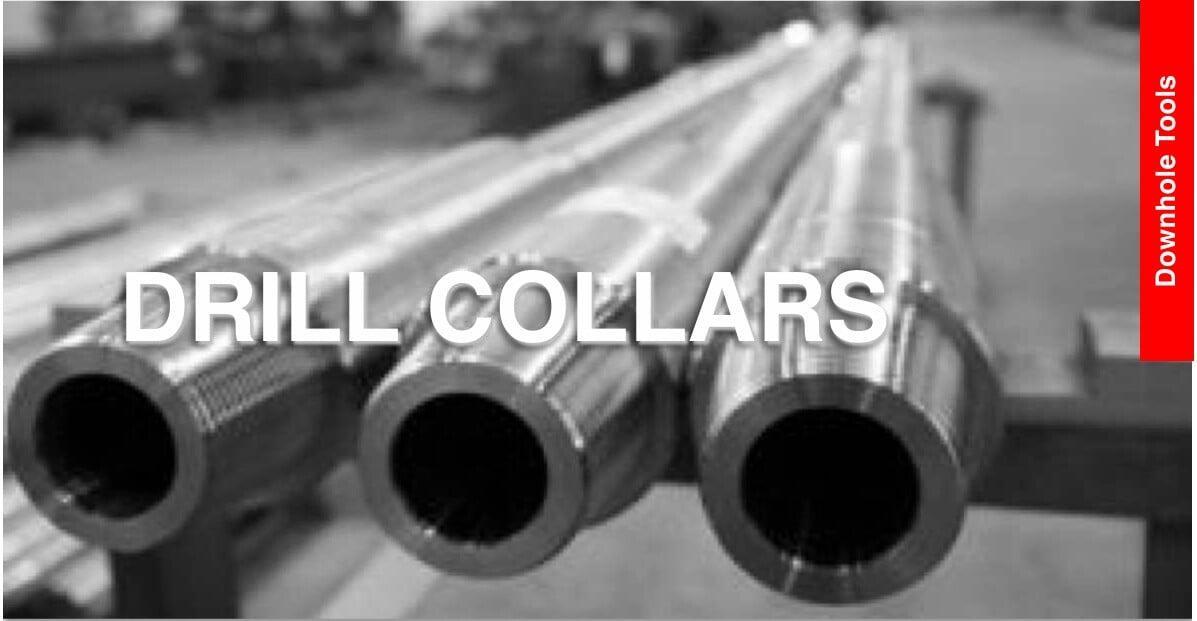

• Drill Collars - Non-magnetic and magnetic

BENFITS AND FEATURES

- Non-Magnetic and AISI 4145 H-MOD 30-36RC material, String and Near bit

- Use of FEC RAPTOR proprietary hard facing for wear and impact resistance in harsh drilling environment

- Manufactured according to API specification

- Large inventory of raw material thus able to deliver faster to suit customer’s urgent requirements.

- Bespoke manufacturing to suit customer specific requirements

- Fast response time

Our stabilizers and sleeves set the standard in both directional and straight hole drilling applications. The all-in-one construction makes it an industry workhorse –able to perform in the most rugged and abrasive drilling conditions. Milled directly into a steel forging, the one-piece rotating stabilizer can be run near the bit or up in the drill string in soft to medium and abrasive formations.

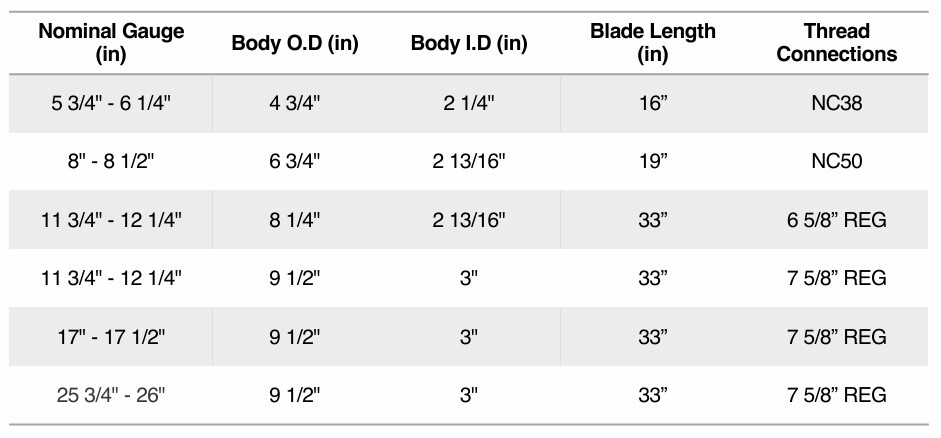

STANDARD INTEGRAL BLADE STABILIZER SPECIFICATIONS

Standard specifications, that can be customized as per customer drawing, size and specifications.

FEC RAPTOR hard facing is our indigenous process that used tungsten carbide based tiled inserts which is used for hard facing parts like stabilizer blades, stabilizer sleeves and radial bearing sleeves. Raptor hard facing uses premium grade of tungsten carbide for wear protection inserts which provides the ideal mix of wear and impact resistance. Once applied to a tool, can be infilled with either metal spray powder or composite rod to offer a wear resistant surface to meet your application needs.

FEC RAPTOR hard facing is our indigenous process that used tungsten carbide based tiled inserts which is used for hard facing parts like stabilizer blades, stabilizer sleeves and radial bearing sleeves. Raptor hard facing uses premium grade of tungsten carbide for wear protection inserts which provides the ideal mix of wear and impact resistance. Once applied to a tool, can be infilled with either metal spray powder or composite rod to offer a wear resistant surface to meet your application needs.

FEC Radial Bearings are made from 4145 H modified quenched and tempered material to API specifications. Manufacturing is on CNC machines to ensure high precision machining. Robust construction ensures superior wear resistance in harsh drilling environment.

BENFITS AND FEATURES

- Non-Magnetic and AISI 4145 H-MOD 30-36RC material, String and Near bit

- Use of FEC RAPTOR proprietary hard facing for wear and impact resistance in harsh drilling environment

- Manufactured according to API specification

- Large inventory of raw material thus able to deliver faster to suit customer’s urgent requirements.

- Bespoke manufacturing to suit customer specific requirements

- Fast response time

BENFITS AND FEATURES

- Non-Magnetic and AISI 4145 H-MOD 30-36RC material, String and Near bit

- Use of FEC diamond inserts for wear and impact resistance in harsh drilling environment

- Manufactured according to API specification

- Large inventory of raw material thus able to deliver faster to suit customer’s urgent requirements

- Bespoke manufacturing to suit customer specific requirements

- Fast response time

FEC PDC bearings are built for superior resistant to wear. Compared with traditional tungsten carbide or other hard alloy bearings, the life of diamond bearings lasts longer, and they can operate at high temperatures (currently the highest temperature is 233°C). The PDC bearing system can absorb excessive load for a long time, and the low friction loss in the bearing assembly further increases the transmitted mechanical power.

WHEN ORDERING, PLEASE SPECIFY

- Drill collar OD and ID

- Overall length

- Connections required (size and type)

- Special features desired, for example: Slick or Spiral, Stress Relief Featuresures

- Drill Collar is the basic component in the BHA which provides weight on the bit for drilling and keeps the drill sting in tension.

- FEC Drill Collars are manufactured from 4145H modified quenched and tempered steel, strict metallurgical specifications are followed to insure that full length heat treating produces a consistent maximum depth of hardness.

- Threads are machined as per API 7-1 specifications or as per customer’s requirement

BENFITS AND FEATURES

- Non-Magnetic and AISI 4145 H-MOD 30-36RC material

- Connections are completed (phosphate coated) to protect them from the elements after machining and to help prevent galling upon initial make-up

- Manufactured according to API specification

- Pressed steel thread protectors are supplied for all drill collar for standard connections

- Large inventory of raw material thus able to deliver faster to suit customer’s urgent requirements.

- Fast response time

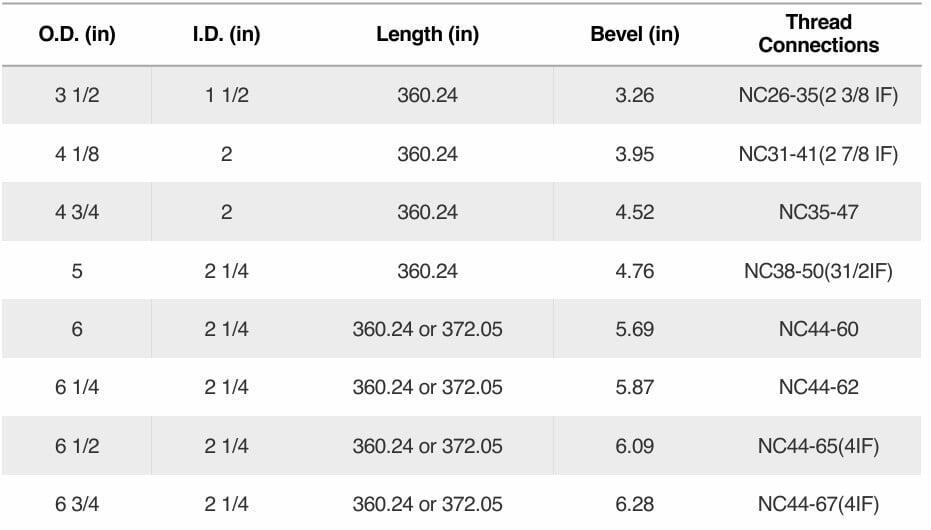

STANDARD DRILL COLLAR SPECIFICATIONS

Standard specifications, that can be customized as per customer drawing, size and specifications

BENFITS AND FEATURES

- Non-Magnetic and AISI 4145 H-MOD 30-36RC material

- Connections are completed (phosphate coated) to protect them from the elements after machining and to help prevent galling upon initial make-up

- Manufactured according to API specification

- Thread protectors are supplied for all standard connections

- Large inventory of raw material thus able to deliver faster to suit customer’s urgent requirements

- Fast response time

Rotary Subs are made from 4145 H modified quenched and tempered material to API specifications, or as per customer’s requirement. They can be used to crossover from connection size to another or as the disposable component used to extend the connection life of a more expensive drill stem member.

TYPES OF ROTARY SUBS

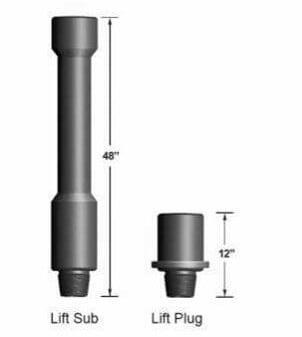

Lift Sub

A Lift Sub enables the safe, efficient handling of straight OD tubulars such as drill collars, shock tools, jars, directional equipment and other tools by using the drill pipe elevators.

Lift Plug

The Lift Plug is a small easy-to-handle sub that makes up in the top of the drill collar. It has a lifting flange that serves as a safety stop when drill collars without elevator recesses are being tripped out of the hole. The center section of the Lift Plug is bored out to reduce weight for easy handling.

Saver Sub

Saver Sub is used to extend the life of the Kelly by taking the connection wear each time it is make-up to a drill stem component. The saver sub connection is sacrificed because it can be easily repaired or inexpensively replaced. The saver sub can be equipped with a rubber protector to reduce BOP equipment and casing wear resulting from contact damage with a lower Kelly connection.

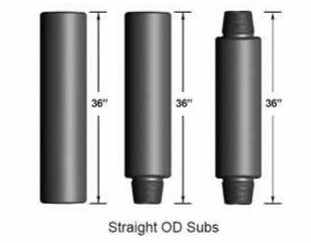

Straight OD Sub

Straight OD Sub is used to connect drill stem members that have a similar outside diameter. The drill bit, downhole tools, heavy weight drill pipe and drill pipe can be crossed over using a straight OD sub.

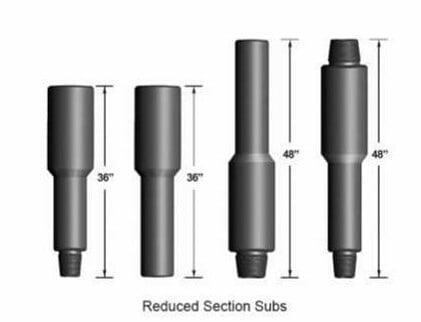

Reduced Section Sub

Reduced Section Sub is used to connect drill stem members that have different diameters that warrant the cross-sectional change necessary to accommodate different connections. This sub would be used to crossover large OD drilling tools or a tapered drill collar string.